Sweetness and bitterness experienced in statue sprucing

Father passed down the craftsmanship to son

Master A-fa founded his own workshop in 1986. From the time he started his business until the turn of the millennium, Taiwan's economy was extremely good. In the 1990s, Master A-fa made statues for many major temples across Taiwan, including the 7.2-foot-tall Jade Emperor, and many other large-scale statues of gods over 5 feet tall. After his reputation was established, his popularity gradually expanded overseas, with a constant flow of customers from Singapore, Malaysia, mainland China and other places, all of whom gave him high praise. Even though his statue sprucing business was prosperous, after nearly two decades of continuous operation, with the subsequent decline of the statue sprucing industry, Master A-fa began to feel tired and think about retirement. At this time, his second son just graduated from the Electrical Engineering Graduate Institute with a master’s degree, and Master A-fa was planning to retire and enjoy a peaceful life. Unexpectedly, his son resolutely gave up his original expertise and insisted on taking over his father’s expertise. Master A-fa said to his son, “If I knew you wanted to learn statue sprucing from the beginning, you wouldn’t have to study hard to get a master's degree!” However, his son’s thirst for knowledge about the craft of statue sprucing eventually moved Master A-fa to pass on his lifelong skills to him. Therefore, Master A-fa has continued to work in the statue sprucing industry for many years until now. Master A-fa’s son gradually established his own reputation, and his craftsmanship was widely recognized. In addition, he participated in many well-known craft exhibitions with Master A-fa.

Master A-fa passes on his craftsmanship to his son.

They participated in many well-known craft exhibitions.

Customized production

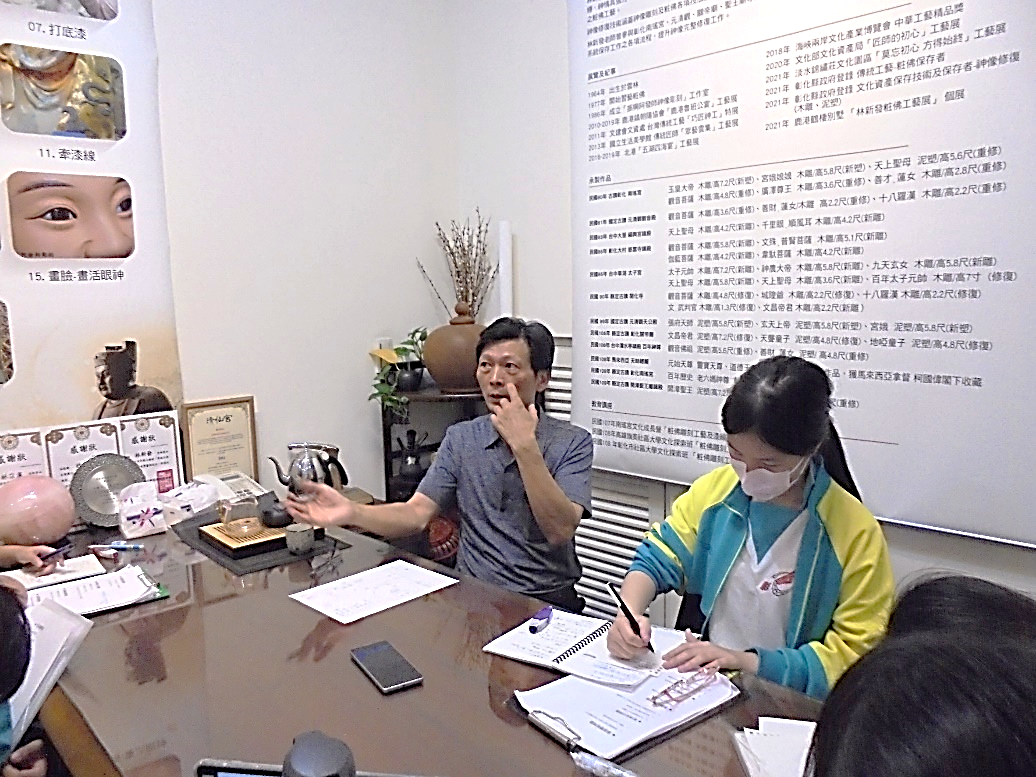

The strength of statue sprucing industry in Taiwan is that in addition to fine workmanship, it can also provide customized services. Master A-fa told us that, in general, when a customer places an order, he will discuss with the customer about their sculpture needs and draw the pattern on paper for confirmation. Some customers have seen the appearance of a statue they like in a certain temple and will provide the style to Master A-fa in advance for reference. Some customers will simply describe their needs verbally, and some customers will directly ask Master A-fa for suggestions. Then, Master A-fa will use his own inspiration to design a style that is acceptable to the customer. After the artwork is completed, the sketch will be painted on the wood before the sculpture begins.

Master A-fa discussed with the customers about their sculpture needs.

Confirming what statue to carve.

On-site production and storage

In general, most of the customers order wooden statues of gods, and clay statues are usually large statues in temples. Since clay statues of gods are prone to cracking and lead to danger if moved, clay statues of gods are almost always made on site. For example, the Wenchang Emperor in the back hall of Guangong Temple in Changhua, Zhang Tianshi and Xuantian Shangdi in Yuanqing Temple are all clay statues made by Master A-fa on site. These clay statues take at least one year to complete. Although clay statues require on-site production, it is very convenient because the temple is located in the city and the transportation is convenient.

Moreover, Master A-fa has also prepared many storage rooms to store materials and half-made statues. However, large statues will usually be stored in the lumber workshop first.

The crafting of large-scale statues.

Large statues will usually be stored in the lumber workshop first.

Rising costs of raw materials

The rising cost of raw materials will also have a direct impact on the statue sprucing industry. Master A-fa said that in recent years, owing to the sharp increase in raw material costs, statue sprucing operation has been under great pressure. Many Buddhist statue shops have gradually transformed and switched to selling only ready-made products. They import low-priced Buddha statues from the mainland China for sale. In this way, they do not need to hoard and take care of raw materials of wood, nor do they have to face the difficulty of not being able to buy materials. As a result, they do not have to bear the burden of rising costs of raw materials. However, the rising costs of raw materials have a significant impact on Master A-fa, who engaged in the production of customized statues.

Recently, the wood used for large-scale woodcarving has been difficult to obtain.

Master A-fa took the customer who commissioned the production of statue a few days ago as an example. The customer hoped to carve a statue of a god approximately140cm high. The width of a statue of this height is relatively large. However, the wood of this size is currently unavailable on the market at a reasonable price, so Master A-fa was unable to undertake this commission. Master A-fa has also suggested that customer switch to clay sculpture. For example, many grade 3 and grade 2 monuments of temples store clay sculptures. Clay sculptures can also be preserved for a long time, which can solve the problem of unavailability of raw materials.

Unfortunately, the customer still intended to commission the production of wood sculpture, so Master A-fa could only decline it. The difficulty in running this business is that the soaring price of materials is not only double or triple the price. For example, the cost of gold used for gold foil laying has increased from NTD 700 to more than NTD 8,000. The cost and price also challenge the wisdom of statue sprucing operators.

The price of gold used for gold foil laying has increased significantly.

Occupational injuries

Statue sprucing requires the use of several tools and long hours of focused work. Master A-fa said, “Taking myself for example, I have suffered from several occupational injuries.” For example, knife wounds, because carving statues of gods usually requires fixing the wood with feet clamped. Master A-fa was once injured because of this. The knife was accidentally inserted into his leg while working, and an incision was required. As age increases, his vision has also declined, making his eyes’ focal length conversion function weaker. Master A-fa pointed to the row of knives in front of him and said, “I used to have good eyesight and I could reach out and pick anything I want up. But now, due to my presbyopia, there are sometimes errors. Unfortunately, because of this slight error, my hand was injured as soon as my hand touched the blade.”

The carving tools are very sharp.

Carving statues of gods usually requires fixing the wood with feet clamped.

Besides, lowering the head for a long time while working puts too much pressure on the cervical spine, which also causes damage to the cervical spine and results in chronic pain. Master A-fa said, “It's impossible to be too far away from the wood when carving! Sometimes when carving delicate parts, I can’t help but get closer and closer, and the angle of my head becomes wider and wider without even realizing it. Over time, even if I raise my head and chest straight, my body can’t be straight while standing.” Moreover, prolonged sitting can also cause damage to the knee joints. Master A-fa said, “When I was young, I didn’t feel it. Over time, the flexion and extension of the joints have become unsmooth, as if there is a clicking sound.”

Prolonged fixed postures at work may cause some harm to the body.

Large amount of dust which also inevitably damage the respiratory system.

Besides, when making wood carvings, the generation of sawdust and dust is unavoidable, and breathing will also be seriously affected. Master A-fa said, “In the past, when I was an apprentice, I mostly used axes for carving, which produced less dust. Now, with the advancement of equipment and attention to precision, I often use electric chain saws, which will generate a large amount of dust that will inevitably damage the respiratory system if inhaled into the lungs.” The lacquer used in statue sprucing also produces a strong odor. Although water-based lacquer with a lighter smell is now used as much as possible, it is less harmful to health than the oil-based lacquer with strong penetrating power. However, it will still affect the respiratory organs. In addition, when carving large statues of gods, it is often necessary to move them around, and sometimes the hands will be crushed by wood because of this. These all are unavoidable occupational injuries!

The lacquer used in statue sprucing also produces a strong odor.

Sometimes the hands will be crushed by wood of large statues.

Those who visited him to learn the craft

When asked if anyone would actively seek apprenticeship from him now, Master A-fa said, “I once met a student from Hsiushui Vocational Senior High School who came to me to become an apprentice when he was at your age. I refused at the time because statue sprucing industry is not easy to operate nowadays. Modern people are living busy lives, and many people have gone to temples to worship gods instead. The need to place statues of gods in their homes is decreasing. How can I agree to him to engage in an industry without future prospects? This child is now in his third year of senior high school. I met him in the temple not long ago. He was very happy to tell me that he paid attention to every post in our workshop. He is currently studying in an art-related department and taught himself to use clay and lacquer thread to sculpt Buddha statues. His works look great and authentic.”

Even though he did not accept him as an apprentice, Master A-fa still obligately gave him lot of guidance. Master A-fa would rather teach the student what he knows when the student is interested and actively ask questions. He taught the student how to use materials, how to make scaffolds, and remind him where should be corrected. Master A-fa takes the matter of accepting apprentices very seriously. Master A-fa said: “Accepting a person as an apprentice means that you have to be responsible for his future!” The traditional sense of responsibility of a master to cherish his apprentices can be clearly observed in Master A-fa’s heart.

Master A-fa also mentioned that there is a child who lives near the workshop. When the child was studying in the elementary school, he often came to watch Master A-fa’s work. One day, the child said he wanted to become my apprentice, and Master A-fa told him, “Don't learn this, statue sprucing is too hard!” Then the child learned how to make dough figurine, and then later learned how to make sculptures, and eventually made statues of a god out of clay. Due to his own interest, that child learned from many masters everywhere. Even though Master A-fa did not accept him as his apprentice, this child now not only knows dough figurine, clay sculpture, but also many other related crafts to create his own path!

In the end the interview, Master A-fa encouraged us to study hard first and focus on laying a solid academic foundation. The career path of statue sprucing crafts is never easy. With the decline of traditional crafts, the future survival of statue sprucing craftsmen is still a huge challenge. However, Master A-fa still hopes that the precious craftsmanship in Taiwan will have the opportunity to be understood by more people, and also hopes that with the attention of the government, people with destiny and talent can pass down this craft. Hopefully, through the sharing of more people, the beauty of local craftsmanship can be seen by more people!

Special Events

To many people, statue sprucing is quite mysterious. In particular, statue sprucing craftsmen often come into contact with gods, Buddhas and religions, which makes people wonder whether they have encountered special supernatural events. Master A-fa could not stop our curiosity. He talked about his experiences: when making Buddha statues, sometimes the gods really come to him in dreams. He said that one time when he was making a statue of Mazu, Mazu gave him instructions in his dream. Mazu told Master A-fa very carefully how to make the statue, how much should be reduced on which side, and how much should be modified on which side. These seemingly supernatural dreams are often the source of inspiration for Master A-fa’s sculptures. These seemingly supernatural dreams are often the source of inspiration for Master A-fa’s sculptures. However, Master A-fa also said that from a scientific perspective, it might be that he thinks about the sculpture during the day and dreams about it at night!

We enjoy listening to Master A-fa telling stories.

From practicality to artistry

We talked about the fact that some statue sprucing craftsmen now also make wood-colored statues of gods for art collection. We also discussed whether “gold foil laying” is required for statues of gods. Master A-fa said that traditionally, gold foil laying aims to make the statue of the god have a golden body that can ward off evil spirits, which is very important. After a statue of the god is attached with gold, it must be worshiped. If a statue is just a collectible, it is not recommended to use gold foil laying. In the current situation of industry decline, creating art pieces is also one of the options that many statue sprucing craftsmen with wood carving skills may consider. Master A-fa said, “I established my workshop in 1986. There were more than 10 workshops in Changhua City alone at that time. Now there are only mine and the other one.” The statue sprucing craft of delicate craftsmanship requires long-term talent cultivation. How the future of statue sprucing can be developed is a big question worthy of all of us thinking about!

.png)